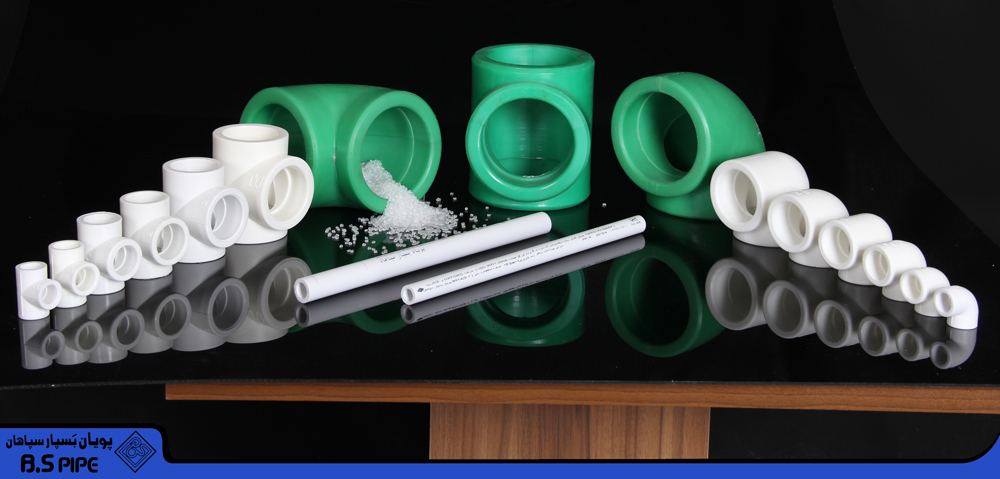

Advantages of pipes and fittings of POOYAN BASPAR SEPAHAN PRODUCTION GROUP

1- No rust, corrosion, decay, and color changes

2- Completely smooth internal and external surfaces and negligible water pressure drop

3- Tolerate 20Pa for cold, warm, and hot water

4- Low thermal, electrical, and transfer conductivity

5- No algae formation in the pipes due to anti-UV matters

6- Completely resistant against acids and basis

7- Lower weight than metallic pipes

8- Easy to install and durability

9- Hygienic

Applications of polypropylene pipes made by POOYAN BASPAR SEPAHAN PRODUCTION GROUP

1- Cold and warm water lines in houses, trade and administrative buildings, hospitals, and hotels

2- Urban and rural water supply lines

3- Compressed air systems

4- Chemicals transmission systems

5- Wastewater transmission networks

Quality control test

Taking into account the fact that POOYAN BASPAR SEPAHAN PRODUCTION GROUP follows optimization of products quality upgrades, our QC Department is trying to supply products conformed to the Iranian and international standards through accurate supervision on all the production phases and doing required tests on raw materials and finished products during / after production.

This company has established ISO 9001:2015 and ISO 10004:2015 international and the European CE standard as well as national and IHUDR standards and has always followed “commitments to the quality”. Management system of POOYAN BASPAR SEPAHAN PRODUCTION GROUP is going to gain customers’ satisfactions through meeting their needs based on requirements and inquiries.

In this respect, Quality Control Department of POOYAN BASPAR SEPAHAN PRODUCTION GROUP supervises all the working and production activities by means of the most advanced QC lab and modern devices based on compiled schedule on hourly, daily, and weekly basis, in order to control all the parameters within standard ranges and minimize process changes.

Quality control works in three scopes: 1) control raw materials; 2) control during production; and 3) control finished product. As such, QC activities in the above three scopes include the followings:

1- Determine international standard factors

2- Measure the factors through standard tests in the lab

3- Compare and analyze the results with international standard indexes

4- Take corrective measures in case of non-conformity results

QC tests on our products are based on the following table:

| Products QC tests | |

| Dimension control tests | ISIRI 6314-1 , ISIRI 7175-4 |

| Conformity evaluation | ISIRI 6314-5 , ISIRI 6314-7 |

| Visual inspection | ISIRI 6314-1 ISIRI 6314-2 |

| Creeping strength test | DIN 53759 EN 921:1994 |

| Taste reactivity test | ISO 9854-1 |

| Molten flow inspection (MFI) | ISIRI 6980 |

| Effect on water test | BS 6920 :port3 |

| Thermal return test | ISIRI 6314-2 ISIRI 7175_3 |

| Impact strength test | DIN 53453 DIN 51222 DIN 8078 ISO 9854 |

| Marking test | ISIRI 6314-2 |

| Opacity test | EN 578:1994 ISIRI 6314-2 |